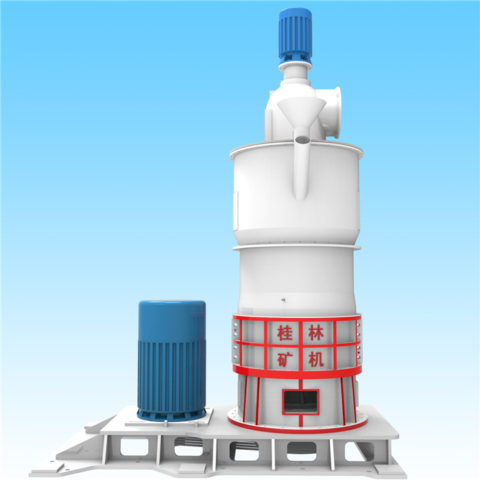

GKH1032D Ultrafine Ring Roller Mill

GK1032D ultrafine mill is new type of grinding mill with optimized structure for specilizing in making micro powder. It is suitable for deep processing non-metallic mineral stone whose hardness less than 6 Moh’s hardness and moisture less than 10%, such as calcium carbonate, kaolin, talc, barite, wollastonite, feldspar, etc. The mill is mainly consisted of feeder, main unit, classifier, pulse collector, high pressure blower, electrical control cabinet.

Application :

GK1032D ultrafine mill is new type of grinding mill with optimized structure for specilizing in making micro powder. It is suitable for deep processing non-metallic mineral stone whose hardness less than 6 Moh’s hardness and moisture less than 10%, such as calcium carbonate, kaolin, talc, barite, wollastonite, feldspar, etc. The mill is mainly consisted of feeder, main unit, classifier, pulse collector, high pressure blower, electrical control cabinet.

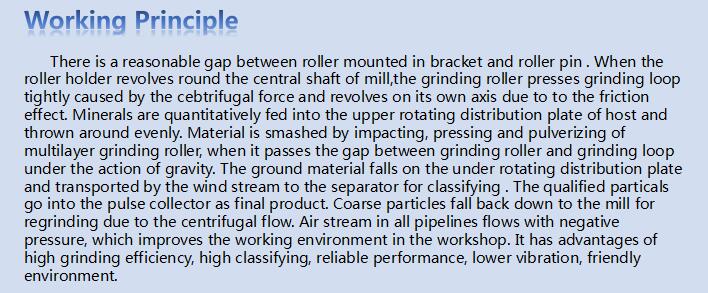

Working Principle

There is a reasonable gap between roller mounted in bracket and roller pin . When the roller holder revolves round the central shaft of mill,the grinding roller presses grinding loop tightly caused by the cebtrifugal force and revolves on its own axis due to to the friction effect. Minerals are quantitatively fed into the upper rotating distribution plate of host and thrown around evenly. Material is smashed by impacting, pressing and pulverizing of multilayer grinding roller, when it passes the gap between grinding roller and grinding loop under the action of gravity. The ground material falls on the under rotating distribution plate and transported by the wind stream to the separator for classifying . The qualified particals go into the pulse collector as final product. Coarse particles fall back down to the mill for regrinding due to the centrifugal flow. Air stream in all pipelines flows with negative pressure, which improves the working environment in the workshop. It has advantages of high grinding efficiency, high classifying, reliable performance, lower

vibration, friendly environment.

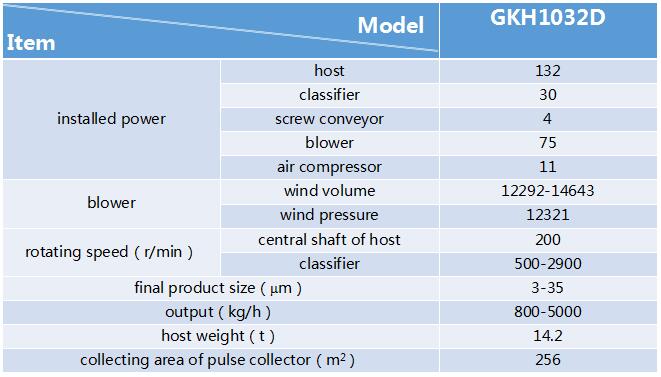

| Item Model | GKH1032D | |

| installed power | host | 132 |

| classifier | 30 | |

| screw conveyor | 4 | |

| blower | 75 | |

| air compressor | 11 | |

| blower | wind volume | 12292-14643 |

| wind pressure | 12321 | |

| rotating speed(r/min) | central shaft of host | 200 |

| classifier | 500-2900 | |

| final product size(μm) | 3-35 | |

| output(kg/h) | 800-5000 | |

| host weight(t) | 14.2 | |

| collecting area of pulse collector(m2) | 256 | |